This is a commision I have just delivered to a local customer. The design is based on something the customer saw on TV, but I didn’t like the legs as each quadrant had three spindle legs which meant 12 legs when the table was together. It looked a bit like a jellyfish when set out as a circle, and a centipede when set out in a wave!

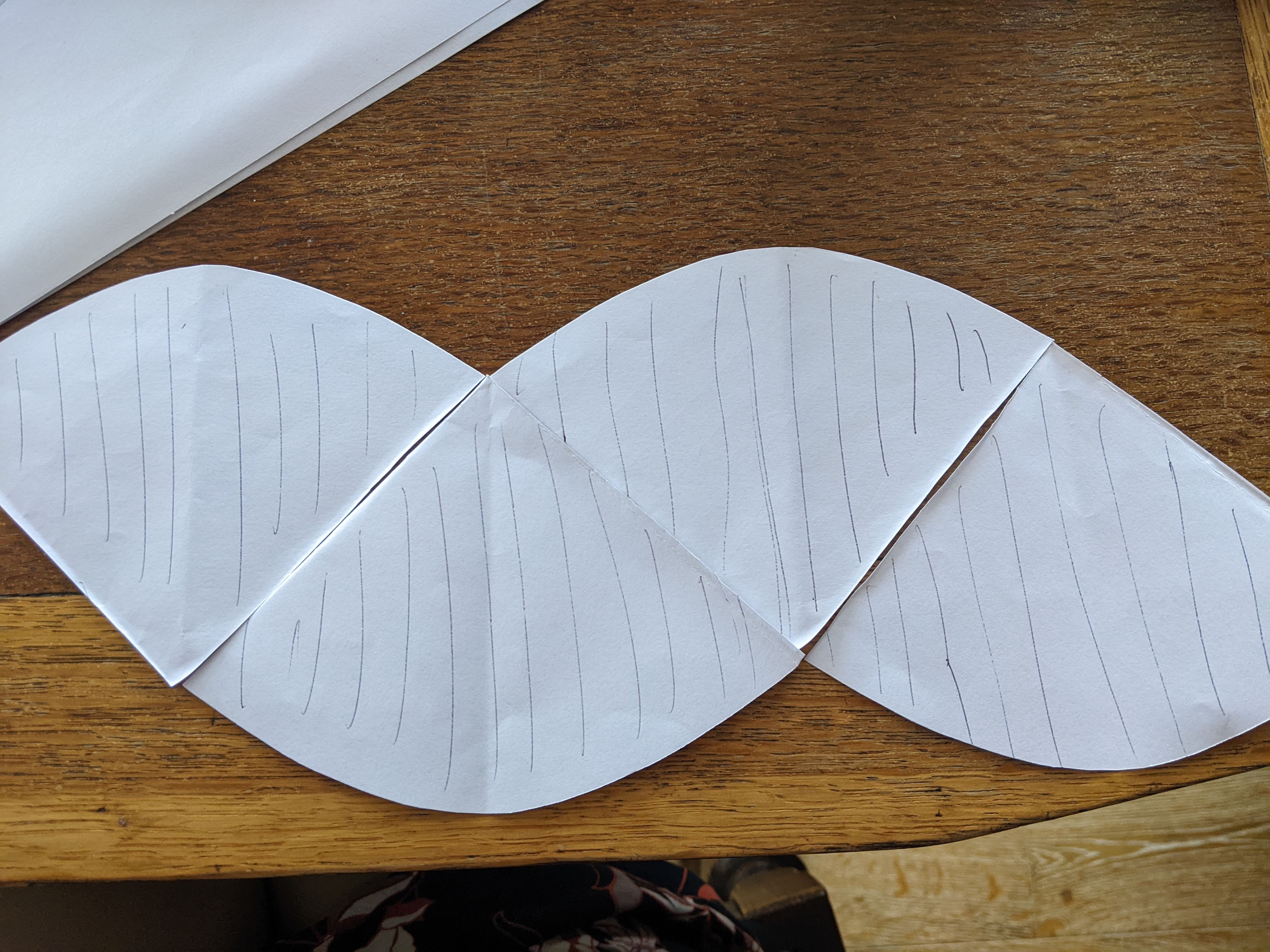

The table top is made of 18mm plywood with beech veneered edges. As I work with portable tools rather than workshop machinery, there were some interesting challenges to overcome in cutting the circles. A further consideration was that the customer wanted the grain of the table to be in the same direction when the tables were set out in a wave. This meant that each quadrant had to be cut separately, rather than cutting one large circle. Jigsaws are not good for cutting regular repeated shapes and also the blades tend to drift preventing the cut from staying vertical. So instead I used a plunge saw to trim diminishing straight lines, then complete the curve with a block plane.

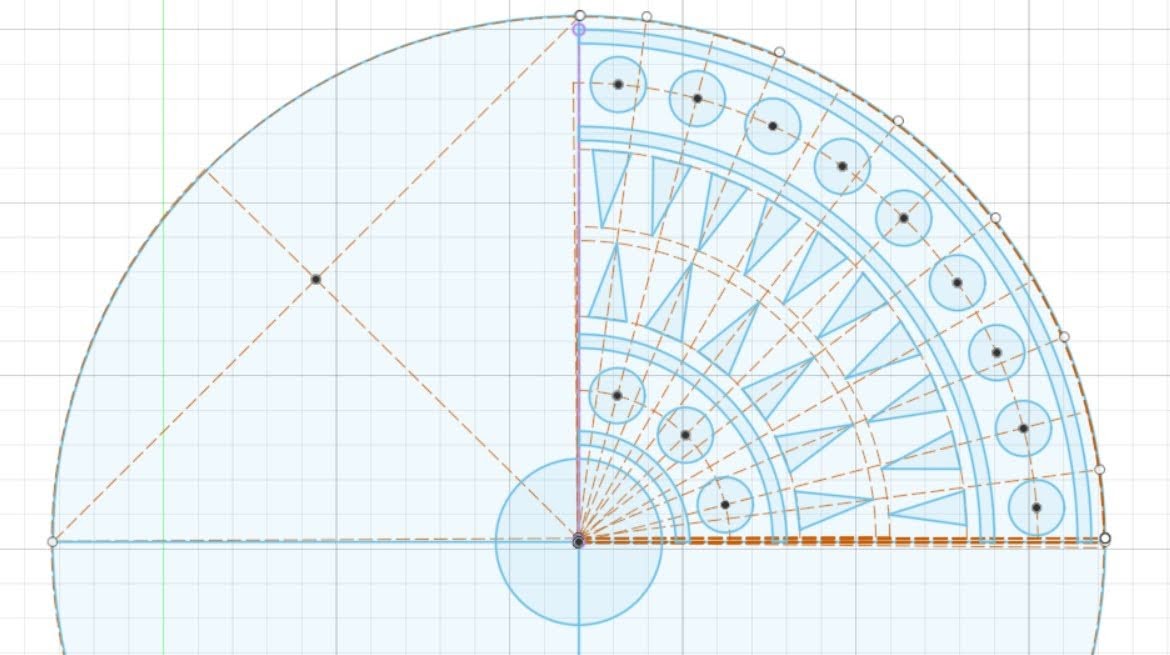

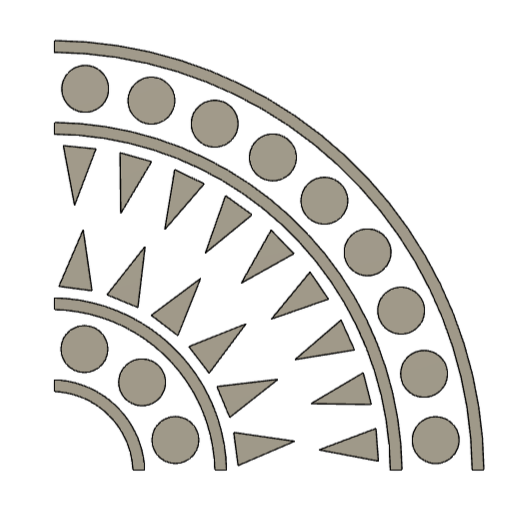

Next I created the table top design in Fusion 360. The design needed to align in all configurations and be evenly spaced. I decided to add an additional boarder band to the inner and outer edges as I felt this looked more finished. I am quite new to Fusion 360 so it did cause me a lot of frustration tryin to get the image print-ready, as well as only being able to export it in file formats that were not compatible with the printing firm. I was advised to send the image as a JPEG, but the loss of quality was so drastic that even if the printing process had been better, the result would still have been very poor. In the end, a design firm was able to translate the final exact image dimensions into an appropriate form. Initially, the printing company suggested a transfer, but it left clearly visible edges, so I opted for a vinyl stencil instead.

Once I was satisfied with the printing trials, I ordered full-size stencils and started considering the table legs. There was a lot of discussion with the customer at this point to meet her requirement for the legs to be fine, whilst ensuring the tables were sturdy and well-balanced. Eventually (as is often the way!) the solution was quite simple and after some further sketches, the leg design was confirmed. At this point I needed to cut a further 12 ply circles and did not want to do this using the straight cutting method I had used for the quadrants. Instead I made a router jig and used a straight cutting bit to cut out the circles which worked really well. After that all the edges were veneered, and all the components were stained and hand sanded with 180 – 240 grit paper, then assembled and finished with matt varnish.

Leave a comment